Autogenous welding and cutting equipment

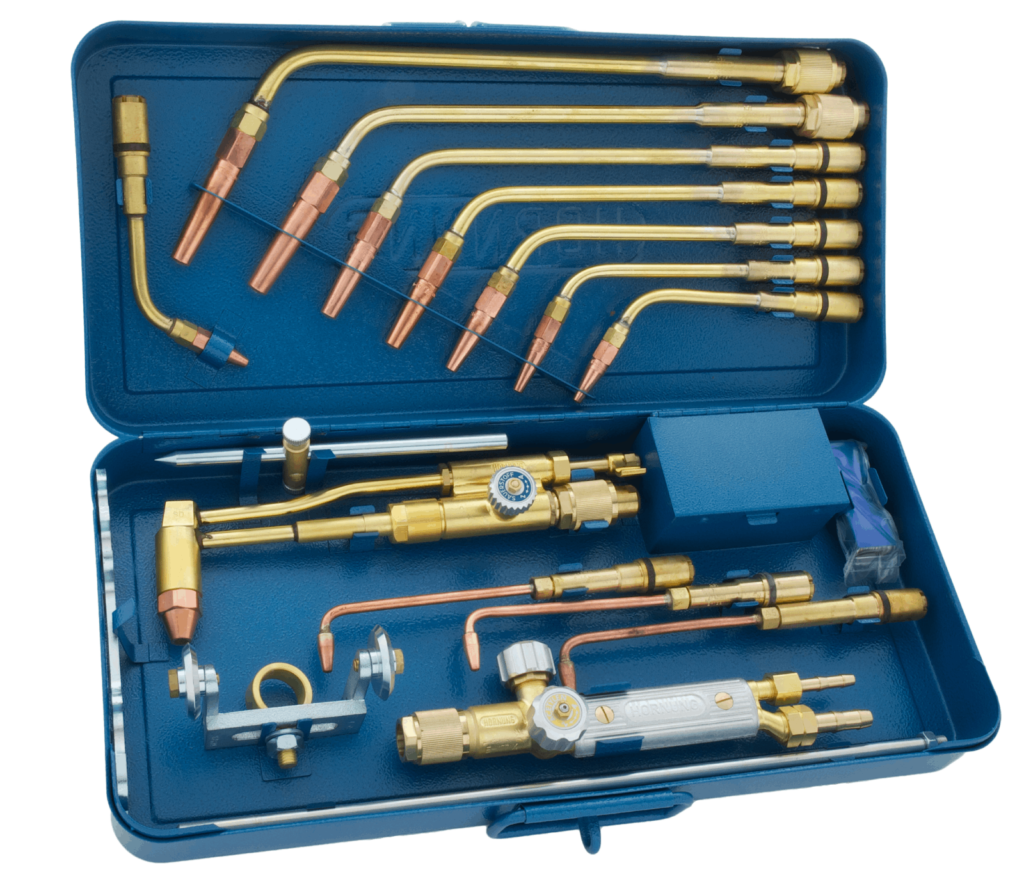

Our fittings are also available in form of complete welding and cutting sets and can be combined in a variety of equipment ranges.

Welding inserts are intended to be used with acetylene/ oxygen as well as propane/ oxygen.

Depending on the configuration, various welding inserts such as a handle with an aluminium grip-shell Model EH/ES or EM, as well as diverse heating and cutting nozzles, and a compass device are a part of the scope of supply.

In particular for the Model Series EHK we offer compact small welding and small cutting sets also supplied in a sheet steel box for delicate welding, cutting and heating applications.

In our product range there are also appropriate cylinder pressure regulators for acetylene, oxygen or propane as well as complete central gas supplies with suitable fittings at the extraction point.

Autogenous welding torches

In an autogenous welding process, two work pieces are welded together – a flame composing of combustible gas and oxygen is generated in the welding torch which prompts the steel via oxidation to melt.

Hornung autogenous welding inserts are available for grip pieces with aluminium grip-shells of the model series EH with a 19 millimetre shaft diameter; EM with a 20 millimetre shaft diameter; ES with a 17 millimetre shaft diameter. These are standard delivery items for the material strength from 0.5 millimetres to 30 millimetres.

Autogenous cutting torches

In an autogenous cutting process, metals are separated via heating up to melting point. First, the interface is heated, then the combustible gas has to be turned off, after which cutting oxygen is directed with a lever precisely on to the interface. Iron then burns down to iron oxide, the liquid metal is blown away and a gap remains.

Hornung autogenous cutting inserts are available for grip pieces with aluminium grip shells of the model series EH with a 19 millimetre shaft diameter; EM with a 20 millimetre shaft diameter; ES with a 17 millimetre shaft diameter. These are standard delivery items for the material strength from 3 millimetres to 300 millimetres.

The single cutting torch Type GD is permanently combined with an in-built grip piece and is especially suitable for gas-mixing and cutting nozzles. Type GD is a standard product available for material strengths from 5 millimetres up to 100 millimetres.

Autogenous heating torches

Autogenous heating torches are deployed for local heat transfer and for hot forming of pre-manufactured parts. Heating torches are also used for pre- or post-heating when welding or cutting.

Hornung autogenous heating inserts and torches with screen heads are available for grip pieces with aluminium grip-shells of the model series EH with a 19 millimetre shaft diameter; EM with a 20 millimetre shaft diameter; ES with a 17 millimetre shaft diameter. These are standard delivery items for the material strength from 4 millimetres to 1000 millimetres.