Applications:

Central gas supply systems are fittings for technical gases. In case of high gas consumption, central gas supply systems for cylinder batteries or bundle battery systems are installed. From this supply system, the gas can be distributed to various point of use regulators and withdrawn at point of use regulators.

The advantages of a central gas supply system from Hornung are:

- No interruption of work due to cylinder changes

- Central monitoring of the gas supply

- Space saving at the consumption points

- Uniform emptying of the cylinders

- Reduced internal transport costs

Area of application:

Central gas supply systems are used, for example, for applications in production plants or in the medical or chemical industry. Gas supply systems for acetylene and oxygen for uninterrupted gas supply are used in particular in welding.

They are also used in laboratories for the supply of technical gases. Battery pressure regulators / central pressure reducers are part of the most fixed central gas supply systems where more than just one gas cylinder is needed for the gas supply.

Applications of the pressure regulating stations include:

- Production plants

- Chemical industry

- Pipeline construction

- Welding technology

- Vacuum hardening furnaces

- Metal production

- Laboratories

Products:

Our central gas supply systems are delivered ready for assembly to our customers. These gas supply systems are available in one-sided and two-sided versions and in different pressure levels with appropriate accessories. For oxygen with BAM combustion test up to 300 bar, as well as for flammable and non-flammable gases and specialty gases:

ZD60 Gas supply station / one-sided and two-sided version

With the ZD60 gas supply station, an inlet pressure of max. 300 bar can be reduced to a pressure of max. 30 bar and kept constant. The ZD60 pressure regulating station is available in brass for non-corrosive, flammable and non-flammable gases.

ZD150 Gas supply station / one-sided and two-sided version

With the ZD150 gas supply station, an input pressure of max. 300 bar at a pressure of max. 40 bar can be reduced and kept constant. The ZD150 pressure regulator station is available in brass for non-corrosive, flammable and non-flammable gases.

ZD400 Gas supply station / one-sided and two-sided version

The ZD400 gas supply station reduces the max. pressure of 300 bar to a back pressure of max. 20 bar. The built-in ZD400 pressure reducer is a membrane-manuated pressure reducer with pre-pressure compensation. A special piston design ensures a high pressure constant. The ZD400 pressure regulator is available in brass for non-corrosive, flammable and non-flammable gases.

Specifically for acetylene:

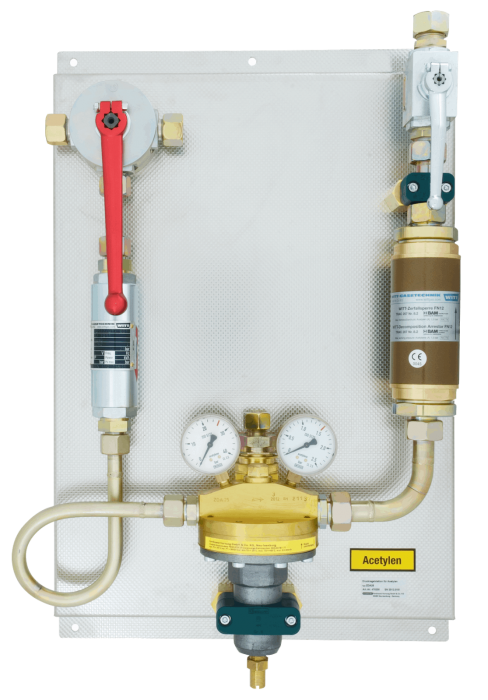

ZDA25 gas supply station

The ZDA25 gas supply station reduces a max. form of approx. 25 bar at a back pressure of max. 1. 5 bar. The pressure regulating station is suitable for installation in acetylene battery or bundle systems up to 2 x 3 bundles. The built-in central pressure regulator is a single-stage brass pressure reducer with safety valve. The large membrane surface causes a very good control behavior.

Accordingly, we also refer to our battery and central pressure regulator (see also the following data sheets):

- ZD60

- ZD150

- ZD400

- ZDA25

Your advantages:

- Precise pressure control for central gas supply

- Can be used for flammable and non-flammable gases and BAM burn-out test up to 300 bar for oxygen

- Special models for use with acetylene

- Compact design for easy installation

- Constant working pressure

- High operational safety due to built-in inline filters

- Best quality, functionality and optimum control behaviour

- Low maintenance

- All models are fully assembled and ready for installation and are also available as a central gas supply station

- Short response times, also for spare parts, due to on-site stock-keeping

In particular, our central pressure regulators/battery pressure regulators and central gas supply stations have proven their reliability, high functionality and durability. Well-known gas companies have been using our products for decades. Consistency and quality characterize our pressure regulators and the satisfaction of our customers confirms our actions.

Profit from our flexibility, short delivery times and product variety. Together we will find an individual solution for your technical application.